Contact us

-

Contacts:Manager Chen

Mobile phone:+86 15662555039

Website:www.guominggroup.com

Address:200m east section of Quyang Road, Linqu County, Weifang City, Shandong Province

Scheme of removing iron from kaolin

Kaolin is an important new type of natural energy, kaolin has been widely used in ceramic paper industry, occupying an increasingly important position. It can not only improve the quality of paper and increase the added value of products, but also meet the requirements of high-quality paper and special paper products. In a long period of time, kaolin will become an ideal choice for high-grade pigment paper.

With the increasing requirements of users for the quality of kaolin products, it has greatly promoted the development of kaolin beneficiation and refining, ultra-fine grinding, calcination, surface modification, dehydration, iron removal and other related technologies and mechanical equipment.

The main impurities in kaolin are iron, titanium and organic matter. Iron and titanium mainly exist in hematite, goethite, pyrite, pyrite, siderite, limonite, anatase and ilmenite. The traditional methods to improve the whiteness of kaolin include physical and chemical methods. The main physical methods include flotation, selective flocculation and magnetic separation. The chemical methods include redox, redox, acid leaching, agent strengthening and bioleaching.

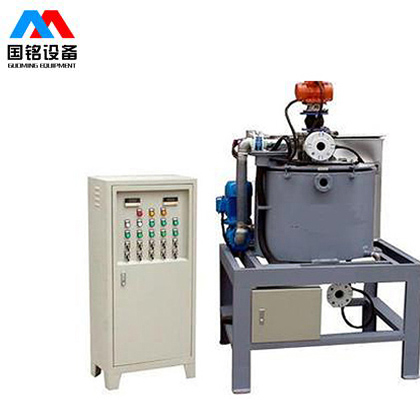

Iron removal by magnetic separation:

Magnetic separation is the use of iron remover to remove iron from kaolin. There are two kinds of traditional kaolin iron removal, dry iron removal and wet iron removal. Customers can choose iron removal process according to different requirements.

Electromagnetic dry powder iron remover

Electromagnetic dry powder iron remover