Contact us

-

Contacts:Manager Chen

Mobile phone:+86 15662555039

Website:www.guominggroup.com

Address:200m east section of Quyang Road, Linqu County, Weifang City, Shandong Province

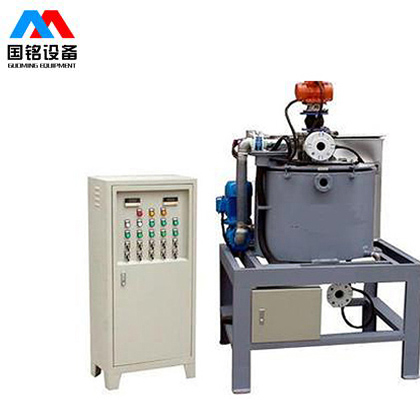

High intensity magnetic iron remover

Product Name: high intensity magnetic iron remover (laboratory small wet high gradient iron remover)

Scope of application:

The equipment is suitable for roughing, scavenging and enrichment of fine weak magnetic ore and iron removal of non-metallic ore. It can effectively treat manganese ore, hematite, pseudohematite, Specularite, siderite, manganese ore, chromite, goethite, limonite, siderite, chromite, niobium tantalum iron ore, ilmenite, wolframite, felsic ore, apatite, yttrium phosphate, olivine, chalcopyrite, germanite, hematite, biotite, epidote, serpentine, primary ilmenite, seashore placer, primary rutile, Wolframite.

working principle:

The materials enter into the magnetic field area through the hopper and the magnetic minerals are adsorbed on the surface of the magnetic roller and rotate to the concentrate area. The brush will brush off the magnetic minerals adsorbed on the surface of the magnetic roller and fall into the concentrate bucket under the jet of high-pressure water. Part of the magnetic particles, non-magnetic particles and weak magnetic particles that are not adsorbed enter the next stage for re concentration.

Technical features:

1. Unique magnetic circuit design, high magnetic field strength, surface magnetic field strength up to 18000gs

2. The brush is made of high polymer wear-resistant material to prolong its service life.

3. The feeding of matching distributing trough is even.

4. It can be combined freely according to the number and size of magnetic roller.

5. The silica sand in the concentrate is washed by high pressure water at the bottom of the tank to reduce the slag and purify the concentrate.

Technical parameters:

Electromagnetic dry powder iron remover

Electromagnetic dry powder iron remover