Contact us

-

Contacts:Manager Chen

Mobile phone:+86 15662555039

Website:www.guominggroup.com

Address:200m east section of Quyang Road, Linqu County, Weifang City, Shandong Province

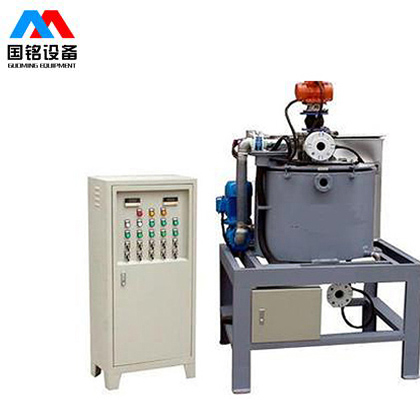

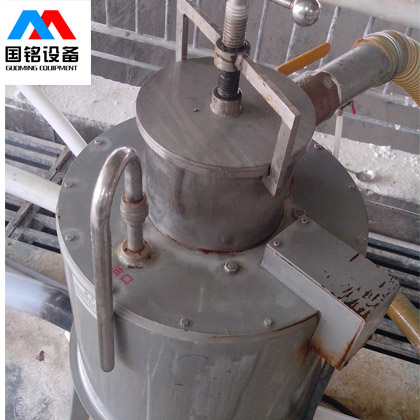

Ceramic material iron remover

When the ceramic material iron removal unit is used, it has the following advantages:

1. The whole SUS304 stainless steel production, stainless steel pipe inner wall after polishing pickling treatment, to ensure that the material will not be polluted.

2. The full-automatic type adopts PLC intelligent control to automatically complete all actions such as excitation, feeding and iron discharging.

3. Forced oil-water mixed cooling, low coil temperature rise ensures the induction magnetic field strength.

4. It has the function of real-time temperature monitoring and automatic control to avoid the coil burning due to the high temperature rise.

5. The brake valve is made of imported material. The valve body is strong and durable, and there is no residual slurry overflow after closing.

6. The magnetic mesh is made of special material. After the power supply of excitation coil is cut off, there is no remanence and it is easy to remove iron.

Technical parameters related to the equipment:

When using the ceramic material iron removal unit, we should pay attention to the correct operation method

1. Open the inlet and outlet valves

2. Close the slurry return valve and iron discharge valve, and open the magnetization device.

3. After a few minutes (it can be set according to the needs), close the inlet and outlet valves, open the return valve, and discharge the remaining slurry in the iron remover through the return valve.

4. Cut off the magnetic field and close the inlet valve, outlet valve and return valve.

5. Open the iron discharge valve to discharge the iron containing substances adsorbed in the magnetic medium.

Electromagnetic dry powder iron remover

Electromagnetic dry powder iron remover