Contact us

-

Contacts:Manager Chen

Mobile phone:+86 15662555039

Website:www.guominggroup.com

Address:200m east section of Quyang Road, Linqu County, Weifang City, Shandong Province

Iron removal scheme for lithium battery materials

Lithium batteries are mainly composed of cathode materials, anode materials, separator and electrolyte. Cathode materials account for more than 40% of the total cost of lithium batteries, and the performance of cathode materials directly affects the performance indicators of lithium batteries, so lithium battery cathode materials occupy a core position in lithium batteries. At present, the market-oriented cathode materials for lithium batteries include lithium cobalt oxide, lithium manganese oxide, lithium iron phosphate and ternary materials. The iron in these materials must be removed, and the purity of iron removal is required to be higher and higher in recent years.

Demagnetization by magnetic separation runs through the whole process of ternary material preparation. The existence of magnetic impurities, especially single iron, will cause short circuit of the battery, which will lead to battery failure in serious cases. The magnetic impurities in ternary materials are mainly the wear impurities of metal equipment and the metal impurities brought by raw materials.

Serial number | Process section | Source of magnetic impurity |

1 | Raw materials and accessories | Nickel sulfate, cobalt sulfate, manganese sulfate, sodium hydroxide, lithium carbonate |

2 | Precursor reaction | Wear or corrosion of metal reactor and metal parts |

3 | Mixture | Abrasion or corrosion of mixing equipment |

4 | Crushing and grading | Wear of crushers and pulverizers |

5 | Material transportation | Pipe wear or corrosion |

It can be seen from the table that the metal impurities are brought in during the preparation of ternary materials.

According to the method of generating magnetic field, it can be divided into permanent magnet iron remover, electromagnetic iron remover, superconducting iron remover and so on.

In the preparation process of ternary materials, the electromagnetic dry powder iron remover is mainly used for iron removal before the packaging of ternary materials. But the finished product of ternary material has a certain weak magnetism, so it needs to use air hammer to knock in the process of magnetic separation.

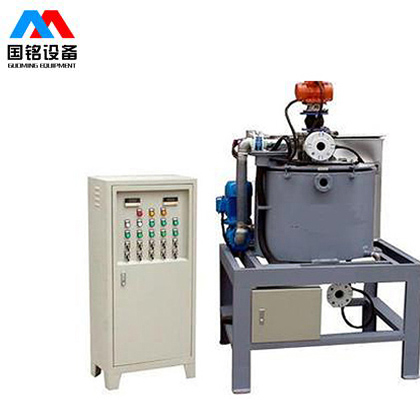

Electromagnetic dry powder iron remover

Electromagnetic dry powder iron remover