Contact us

-

Contacts:Manager Chen

Mobile phone:+86 15662555039

Website:www.guominggroup.com

Address:200m east section of Quyang Road, Linqu County, Weifang City, Shandong Province

Scheme of removing iron from refractories

Recovery and utilization plan of refractory brick / box platinum:

Because of the complex refractory variety and the variety of raw materials used, the types of refractories after use are various. For the treatment of the refractory after use, different treatment techniques should be considered in terms of the erosion, the use position and the type of refractory. At present, domestic steel mills often stack the refractory materials after use, which results in the mixing of different types and grades of refractory materials, which is difficult to classify and select, which is not good for the recycling of refractory. The treatment of refractory after use shall be considered from the following aspects.

1. the steel plant shall classify and stack the refractory materials according to the different parts and varieties used, so as to facilitate the selection and prevent the entry of mixed and harmful substances.

2. for the post use Refractory stacked by classification, the refractory shall be treated separately according to the sintering degree and erosion. First, manual selection is carried out to remove iron, steel and slag on the refractory surface.

3. for the erosion and bonding strength of different refractory materials, different methods shall be adopted for treatment.

4. for functional elements such as sliding plate, the eroded parts can be removed and combined treatment can be carried out for the abandoned parts due to a small amount of damage, and new products can be prepared for reuse.

The following describes the different erosion parts:

1. severely eroded working and transition layers:

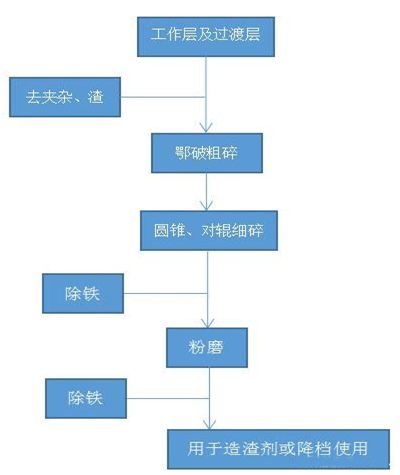

The recycled materials prepared by the working layer and transition layer are treated and prepared according to the process below for slag making agent or downshift.

Figure 1 treatment process of working layer and transition layer

2. Non working face (original brick layer)

According to the sintering degree of non working face, different treatment processes are adopted. The magnesia carbon brick and castable are respectively described below.

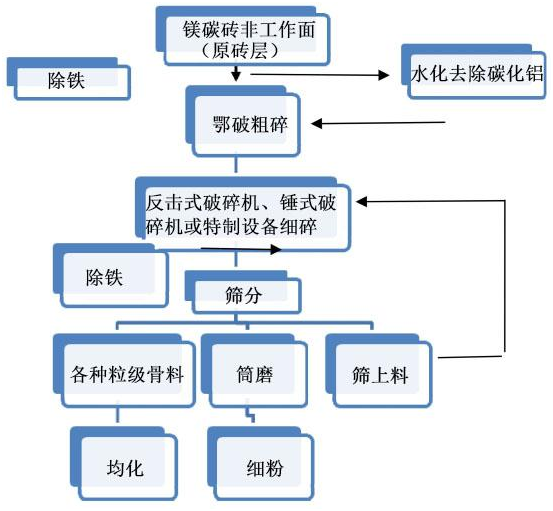

① Magnesia carbon brick mainly depends on resin curing to form carbon network structure, so that the product has strength. However, after use, the non working face of magnesia carbon brick does not form ceramic bonding basically, and the bonding strength between material particles is relatively weak, so the treatment process in Figure 2 can be used.

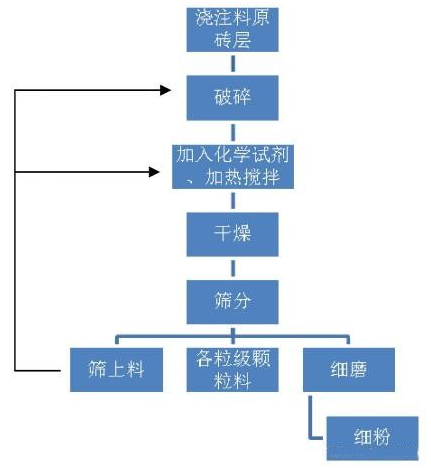

② For the used castables, the coarse crushing is carried out first, and then the crushed particles are put into the aqueous solution of additives for soaking, so as to reduce the bonding strength between particles. After the soaking, the qualified recycled materials are prepared by fine crushing, iron removal, screening, flotation purification and homogenization treatment, which are used in the production of refractories. The process flow is shown in Figure 3.

Fig. 2 treatment process of original layer of used magnesia carbon brick

Fig. 3 process flow of castable treatment

③ For the non working layer which has formed the ceramic combination, because the ceramic combination is formed inside the material, the combination strength between the material particles is high. After simple crushing treatment, the content of false particles in the recycled material is high, the volume density of the material is low, and the porosity in the material is high, which affects the utilization of the recycled material, Therefore, for the reuse of this kind of refractory, the crushing time is often extended in the process of fine crushing, and the content of false particles is reduced by repeated grinding. The amount of fine powder produced by this treatment process is large, and the content of impurities in the fine powder is high.

To sum up, in order to improve the reuse rate of used refractories, the researchers of refractories should focus on the recycling process of refractories and the special production equipment used in the recycling process, and adopt different treatment processes for different varieties to process the non working layer of used refractories, so as to prepare high-grade recycled refractories.

Electromagnetic dry powder iron remover

Electromagnetic dry powder iron remover