Contact us

-

Contacts:Manager Chen

Mobile phone:+86 15662555039

Website:www.guominggroup.com

Address:200m east section of Quyang Road, Linqu County, Weifang City, Shandong Province

Iron removal by quartz sand

Source of iron impurities

The source of iron in quartz is mainly in two aspects: one is the impurities in quartz itself, which may be derived from quartz over the years; Second, the iron mixed in by the outside world. It can be divided into the following categories:

(1) Iron in the slime attached to quartz: other minerals in the slime may have iron impurities.

(2) Iron oxide formed on the surface of quartz: quartz is white in pure condition, and it appears gray, brown, yellow or even red after being polluted. Iron oxide makes the quartz sand yellow or red.

(3) Inclusions in quartz sand: formed over the years.

Method of removing iron impurities

Quartz sand purification is a high difficulty separation technology to remove a small amount of impurities in quartz and obtain refined quartz sand or high purity quartz. In recent years, the research on quartz purification technology at home and abroad mainly focuses on the following aspects:

(1) Water washing and grading desilting

(2) Scrubbing

(3) Magnetic separation

The magnetic separation process can remove the hematite, limonite and biotite and other weak magnetic impurities minerals including the continuum particles to the maximum extent. The wet type or high gradient flat magnetic separator is usually used for strong magnetic separation. Generally speaking, for quartz with weak magnetic impurities such as limonite, hematite and biotite, the wet strong magnetic machine can be selected at least 10000 ostat; For the strong magnetic minerals with the impurity mainly magnetite, the weak magnetic machine is used to select or the medium magnetic machine, and the magnetic separation number and magnetic field strength have important influence. With the increase of magnetic separation times, the iron content gradually decreases, and the iron content can be removed under certain magnetic field strength. However, even if the magnetic field strength is increased a lot, the iron removal rate has not changed much. In addition, the finer the grain size of quartz sand, the better the iron removal effect, the reason is that the high amount of iron impurities in the fine quartz sand. When there are many impurities in the original quartz sand, only scrubbing, desilting and magnetic separation can not be used to purify quartz sand into high purity sand. In order to further improve the purity of quartz and reduce impurities

(4) Ultrasonic iron removal

(5) Flotation

(6) Acid leaching

(7) Microbial leaching

In conclusion, no matter the iron removal method, it has irreplaceable effect in the whole process of quartz sand purification. In practical application, physical methods are often used for pretreatment, such as water washing and grading desilting, scrubbing, magnetic separation, flotation and ultrasonic method, removing most of the impurities, and then chemical methods, namely acid leaching and complexation, to further remove trace impurities in quartz sand. However, the acid solution used in chemical methods has serious pollution to the environment. Therefore, it is necessary for us to seek a new and pollution-free purification method and combine the professional knowledge of chemistry, physics, mechanical chemistry, electromagnetic (wave) chemistry, etc., to study the purification technology of high purity quartz sand is an important economic and social benefit. Especially with the development of microelectronics and optoelectronic industry, the excellent properties of high purity quartz sand are irreplaceable by other powders, and the market prospect is broad.

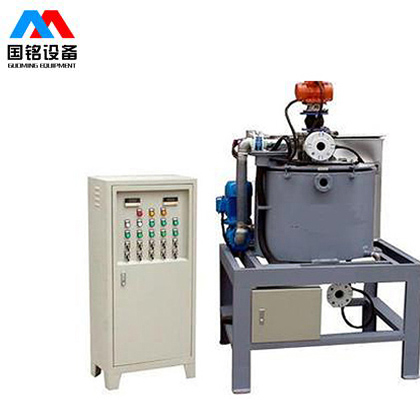

Electromagnetic dry powder iron remover

Electromagnetic dry powder iron remover