Contact us

-

Contacts:Manager Chen

Mobile phone:+86 15662555039

Website:www.guominggroup.com

Address:200m east section of Quyang Road, Linqu County, Weifang City, Shandong Province

Iron removal scheme for ceramic raw materials

At present, with the scale of ceramic industry, the consumption of raw materials is huge, and the high-quality raw materials produced by nature are less and less. Therefore, it is very necessary to optimize the mineral processing of natural raw materials. At present, iron removal is a priority in the design of production line in raw material industry.

1. In kaolin minerals, iron oxide is in the majority, and even iron ions enter into the kaolin lattice, so it is particularly important to use targeted iron removal equipment, such as automatic glaze iron removal machine;

2. In the conventional raw materials of the ceramic industry, the quartz mineral itself contains almost no iron except for the yellow skin on the surface, but mechanical iron will be brought in during the processing. It is very necessary to use strong magnetic iron remover for effective iron removal, such as automatic dry powder iron remover and belt iron remover;

3. In feldspar minerals, mica, tourmaline and other minerals are often associated, and manganese minerals may also be associated. When arranging iron removal, the iron remover with strong iron removal strength should be selected.

PS: iron removal can obviously improve the whiteness and quality of raw materials. But the occurrence form of iron in different minerals is different, iron removal can not be a general introduction, we must refer to the specific actual situation to configure iron removal equipment Oh!

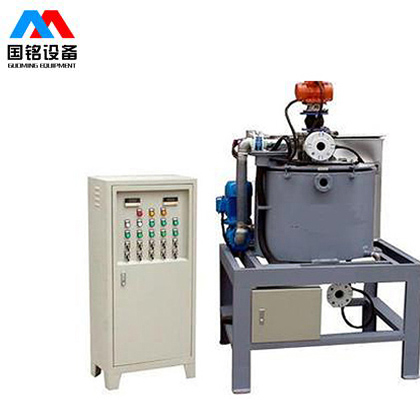

Electromagnetic dry powder iron remover

Electromagnetic dry powder iron remover