Contact us

-

Contacts:Manager Chen

Mobile phone:+86 15662555039

Website:www.guominggroup.com

Address:200m east section of Quyang Road, Linqu County, Weifang City, Shandong Province

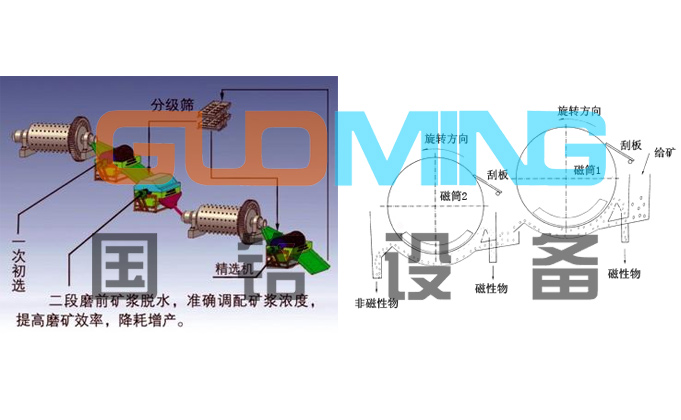

Scheme of iron powder refining

Generally, the process of wet magnetic separation of iron concentrate is adopted

The steel-making sludge is put into the slurry making tank. Firstly, it is soaked in water. Then, the steel-making sludge is impacted by high-pressure water gun and appropriate water is added to make the steel-making sludge slurry reach the specified fineness. The steel-making sludge is transported to the material box of magnetic separator by mud pump through the screen in the slurry making tank. At this time, the iron concentrate and tailings are separated by the magnetic separator, and the iron concentrate slurry flows into the dewatering tank for dehydration and storage, The tailings slurry is discharged into the tailing pit. The iron powder in the steelmaking sludge can be completely recovered by this method, so as to maximize the utilization of resources. The economic and social benefits are very considerable.

Extracting iron concentrate from steel slag: the steel slag is dried by rotary dryer to make the water content of steel slag less than 1.5%. The dried steel slag is sent to electromagnetic pre magnetizer for pre magnetization, and then sent to pre homogenization warehouse for homogenization and storage, and then dry pre grinding is carried out to separate the steel particles of more than 3mm from the steel slag powder of less than 3mm, Then, the steel slag powder less than 3 mm is selected by wind power separator, so that the steel slag powder is divided into two levels of particles larger than 180 mesh and less than 180 mesh. The particles larger than 180 mesh are put into a double barrel dry permanent magnetic separator for ferromagnetic separation. After magnetic separation, the steel slag powder is demagnetized by an electromagnetic demagnetizer, so as to reduce the specific magnetization coefficient of steel slag powder and remove magnetic agglomeration, Then the demagnetized steel slag powder is sent to the ball mill for fine grinding to less than 180 mesh, and the steel slag iron fine powder and steel slag fine powder are separated by the powder separator.

Iron concentrate is extracted from refractory pyrite

The slag discharged from fluidized bed furnace is mixed into pyrite as raw material. The slag is discharged to the slag conveyor through the slag discharge pipe, sent to the humidifier, and then sent to the raw material yard by the slag discharge belt. The slag is mixed into pyrite according to the calculated proportion to form the raw material into the furnace, and then roasted by the raw material into the furnace device. In addition to sulfuric acid, the product can also obtain iron concentrate with iron content ≥ 63%. It opens up a new way for the deep development of pyrite, makes greater use of pyrite resources, and improves the economic benefits of the existing sulfuric acid plant.

Electromagnetic dry powder iron remover

Electromagnetic dry powder iron remover