Contact us

-

Contacts:Manager Chen

Mobile phone:+86 15662555039

Website:www.guominggroup.com

Address:200m east section of Quyang Road, Linqu County, Weifang City, Shandong Province

Iron removal scheme for positive and negative electrode materials

The electromagnetic dry powder iron remover and electromagnetic slurry iron remover produced by our company are especially suitable for separating fine mineral powder particles and slurry. Such as carbon, manganese dioxide, alumina, graphite, electronic anode and cathode materials, ceramic embryo material, etc.

At present, there are many positive and negative materials for batteries, such as lithium cobalt oxide, lithium manganese oxide, lithium nickel oxide, ferrophosphate and ternary. Structurally speaking, lithium cobalt oxide is the most unstable, but its compaction density is the highest, which is beneficial to the miniaturization of batteries. As a new green source, lithium-ion battery has been the focus of attention from all walks of life. With the progress of science and technology, lithium-ion batteries are gradually applied in the field of power, energy storage and other large capacity batteries.

There are many problems caused by metal impurities in cathode materials. It has a great influence on battery discharge and safety. Metal foreign bodies exist in small amounts in products, and the level is ppb. However, no matter how much the amount is, it will cause different degrees of damage to the battery. In addition to the commonly known elemental iron, metal foreign bodies also include CN, Zn, Ni, etc., which exist in the form of elemental matter. Some of these impurities are magnetic, Most of the magnetic impurities can be removed in the production process of cathode materials by iron removal equipment, so that the content of magnetic impurities can reach below 10ppb (according to the calculation of the existence of a single iron substance, the content of self generating electricity of the positive plate of the battery is 35ppb), which can greatly reduce the risk, So the existence of the material is not completely uniform, so there is a low voltage condition of the battery part. It is predicted that LiFePO4 battery will become the mainstream of power battery in 2-3 years.

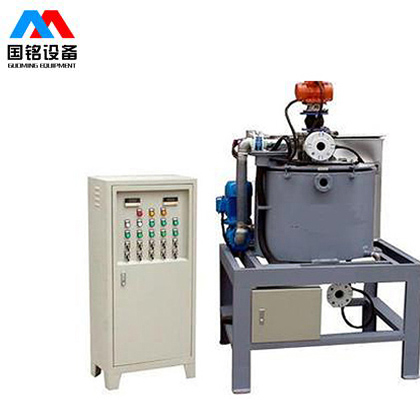

Electromagnetic dry powder iron remover

Electromagnetic dry powder iron remover